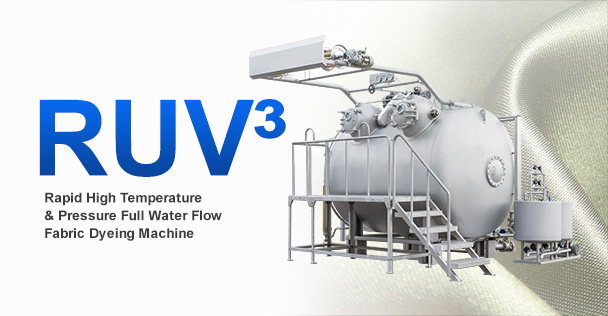

RUV³ Series Low Liquor Ratio Dyeing Machine

ADVANTAGES

Low circulation ratio

The total liquid ratio is the fabric’s liquid absorption plus the machine’s circulation ratio. The fabric’s liquid absorption will differ according to different types of fibers and structures. Therefore the total liquid ratio will change. New design with low circulation ratio, more energy efficient, more eco-friendly.

Constant liquid ratio control

Due to the fabrics being made in many different weights per unit length, thus the maximum weight and maximum length of loading capacity are different for each type. When loading capacity is at 80% ~ 100%, it’s designed to maintain a constant liquid ratio. Therefore, this design increases the stability of the dyeing quality and decreases the uneven batch dyeing.

“ V ” route Plaiting Device

Unlike the traditional plaiting device only folds the fabric in the horizontal direction. The new plaiting device will fold the fabrics horizontally in an orderly fashion and continually follow a “V” route path, thereby increasing capacity compared to the traditional one. For lightweight fabrics (< 200g/yard), can load two ropes per chamber. This fully utilizes the chamber space more and avoids tangling problems, which provides higher quality and more production capacity.

Lowest Tension, Full Water Flow Guiding Pipe Design

Low reel height and lower tension design, combined using a low-pressure overflow nozzle, will reduce fabric tension, pilling & yarn sliding. Follow with a “U” shape full water flow guiding pipe, increase fabric’s saturation for more even coloring and crease free for high-quality dyeing. Suitable for various types of light and heavy fabrics.

Fast Rinsing System

With level rinsing, overflow rinsing with timer or Intelligent rinsing (option), reduce total process time, reduce the energy and lower the cost.

Easy Operation & Fully Automatic Control

Rapid dyeing machine compatible with various brands of controllers. Has fully automatic control and can be upgraded to a central control system for better management. It provides auto dosing control (a continuous stable dosing control), also with fast filling, draining, and hot water tank (option) to reduce total process time. Enhance production yield.

Advanced, Compact Design

The low liquor ratio dyeing machine’s height is operator-friendly, simple, and safer for operation. Low maintenance, low energy cost & high production capacity. Combined with eco dosing device, allows chemicals and dyes to mix with water more evenly before in contact with the fabrics. Suitable for more sensitive fabrics.

Optional Extras

- High-speed draining.

- Water in the flow meter.

- Hot water tank.

- Second chemical tank.

- Dual water in & out.

- Multi-rate feeding device.

- Chemical tank mixing device.

- Swinging device for an outer reel.

- Intelligent rinsing system.

- P.H. sensor & automatic acid dosing.

- Proportional valve for heating & cooling.