Company history

2021

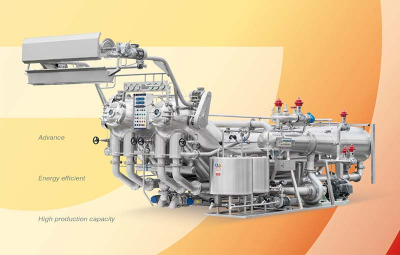

- The revolutionary upper type HEHP dyeing machine with no fabric wheel is launched, it has a lower fabric tension which solves the problem of light fabric being easy to vertical crease marks. New structure design, less wastewater, more energy efficient and eco-friendly.

2019

- Construction of the new factory is completed. Structure beam erection Ceremony held at 2019.07.16

2018

- Construction of new factory started. Groundbreaking Ceremony held on 2018.06.11.

2017

- Launching HEAP, a long tube upper flow dyeing machine, which can dye a wider range of fabrics with high-quality results and also integrate with more automatic sensors and data for operation and analysis.

- Planning a new factory to increase production capacity in response to market demand.

2016

- Introduced a new HEJP model downflow low-energy dyeing machine, which can reduce energy consumption while preserving the quality of dyed fabrics. It is a new achievement for the dyeing and finishing industry, which has been demanding strict environmental protection from all over the world.

2015

- Launched a dual-flow energy-saving yarn dyeing machine, which can effectively reduce the electricity consumption of the machine by 30~40% without reducing the production capacity.

2013

- Launched new O-type RUV2 with a unique "V" route Plaiting Device, which increases the loading capacity of the dyeing machine, improves the customer’s output and reduces the liquor ratio to 1:4.5.

2010

- Improved yarn dyeing machine, developed an efficient built-in pump, reduced the liquor ratio to 1:5.

2008

- Energy saving and carbon reduction are a worldwide trend. R&D introduced lab sample machine TSD-32, to correspond with large machines which has low liquid ratios. This allows customers to dye sample fabrics at a lower cost and with a higher quality result. Also launched low liquid ratio infrared sample machine sets for yarn dyeing, CHS, CDS and CWS.

2006

- Another new O-shaped dyeing machine, ROR. It has a Unique Self Rotating Chamber, fabrics inside this chamber can move from rear end to the front end effortlessly, replacing the use of water to move the fabric. The liquid ratio is at 1:5.

2004

- Accomplished CE inspection to meet the requirements of the European market, Turkey, and other countries requesting CE inspection. Launched ean xtreme high capacity 2400kg O-shaped dyeing machine model name: RUS.

2003

- We launched long tube HEF, which can be divided into two chambers with a single tank. Designed with less excess water storage space in the tank, with the cooling water and washing function between the heater and the dyeing tank.

2001

- Global energy crisis causes the fabric dyeing industry to face growth in energy costs. Fortunately, we launched an O-shaped energy-efficient dyeing machine to further reduce energy consumption.

1998

- Startup company “Hangzhou Donglin Dyeing & Finishing Machinery Co., Ltd.” is located in Hangzhou, China. Starting with 300 employees, making dyeing machines and providing sales & services to China markets.

1997

- Introduced automatic linear and circular welding machines and enhanced the production efficiency, reaching 400 sets of machines per year.

- Evaluate and plan an investment in China, to provide services and manufacture dyeing machines in the China market.

1994

- With energy saving demand, launched new model, NON-REEL~ROL full flow with fabric impact expansion design was launched. It has a lower liquid ratio and higher speed production, and also with higher fabric quality.

1993

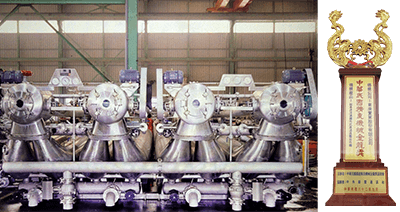

- With the hard work of the RD team, we obtained Precision & design award with Extreme-rapid High-temperature & High-pressure Fabric Dyeing Machine.

- Launching a capacity of 1200kg per machine set. It’s the first machine in the Asia market to have this capacity. A new achievement which greatly increases the production capacity of the dyehouse and decreases the uneven color between machine sets.

1989

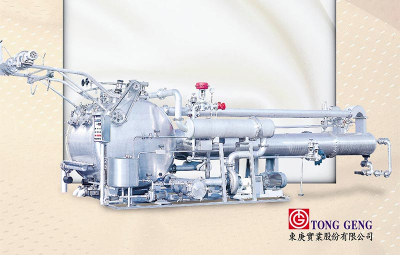

- Tong Geng was established in Guanxi. With over 30 years of experience in dyeing machine manufacture. We continuously serve in the textile industry by providing advanced and energy-efficient products.